Police & First Responders Find Brake Noise Solution

Following up on our previous Press Release (August 20, 2024), PureForge brake technology is now on over 20 different Police and Municipality Fleet Departments across the US.

Recently the Police Department of Huron, South Dakota equipped three different Chevrolet Tahoe PPVs with Atomic-Forged Brakes. Captain Jason Bechtold reported “All three sets are installed, are performing very well, and we don’t have the brake screech like before” (January 2025).

Gordon Heidacker, CEO of PureForge, says,” A unique aspect of Atomic-Forging technology is that we can address several traditional braking problems such as noise and longevity. PureForge Brakes has REAL proven advantages that address customer noise complaints, and the technology can provide real COST SAVINGS (TCO) tied to durability performance and confirmed longevity”.

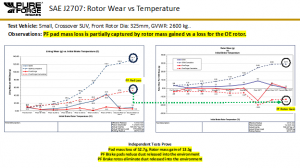

We conducted the SAE J2707 Rotor Wear and Pad Wear vs Temperature test with Link Engineering. We can prove that the PureForge treated rotor and pad formulation wore significantly less when compared to the OEM pad and rotor solution.

The Atomic-Forged treated rotor GAINED 13.5g, and the OEM rotor lost 29.10g. The OEM pad lost 131.7g, and the PureForge pad lost only 52.7g. Yes, the PureForge brake axle kit had less pad wear, and the rotor gained mass and dimension.

No rotor wear, less pad wear = longevity and reduced cost of operation. See chart

“Our brake technology provides a host of features and benefits that add real value to any braking application; we know that PureForge technology is a perfect fleet solution for the owner who is writing the checks,” added Heidacker.

Features and added benefits such as:

• Extended rotor and pad life

• Friction surface rust control

• Reduced brake fade

• Decreasing rotor and pad dust

• More consistent brake pedal feel

• Reduction of lateral runout and disc thickness variation (DTV)

• Laser serialization

PureForge Brakes now has inventory available for high-volume vehicles to fleet owners everywhere. We now have over 950+ vehicle applications, including Police Vehicles from Chevy, Dodge, and Ford.

Additionally, we are proud to announce a partnership with the Fraternal Order of Police (F.O.P.). The F.O.P. has equipped the Disaster Area Response Team “DART” tow vehicle with Atomic-Forged technology.

For more information or to order products, visit our website: www.pureforge.com or please contact:

Dave Sherman

PureForge

+1 248-481-7096

email us here

Distribution channels: Automotive Industry, Building & Construction Industry, Business & Economy, Energy Industry, World & Regional

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release