Isostatic Pressing Market to Soar USD 27.5 Billion by 2035 Amidst Booming Demand in Aerospace, Medical, and EV Sectors

Isostatic pressing drives high-performance, reliable manufacturing in aerospace, healthcare, and EVs, with APAC leading growth and the West driving innovation.

NEWARK, DE, UNITED STATES, May 23, 2025 /EINPresswire.com/ -- The global Isostatic Pressing Market is projected to grow from USD 10.54 billion in 2025 to an impressive USD 27.5 billion by 2035, expanding at a CAGR of 10.1% over the forecast period. This surge is fueled by expanding applications across aerospace, medical implants, and additive manufacturing. With increasing emphasis on producing defect-free, high-strength components, Hot Isostatic Pressing (HIP) and Cold Isostatic Pressing (CIP) technologies are at the forefront of material processing innovation.

In an age of rising performance expectations and stringent safety regulations, isostatic pressing offers a precision path to excellence. Aerospace jet engines, orthopedic implants, and even next-generation EV battery casings are now leveraging isostatic pressing methods to ensure unmatched reliability, longevity, and strength.

The Asia-Pacific region stands out as the primary growth engine, backed by extensive industrial investments and manufacturing scale. Meanwhile, North America and Europe are expected to lead in technology innovation and regulatory compliance, spurring the adoption of smarter, more sustainable production methodologies.

As global governments push for energy-efficient, automated systems, companies that fail to modernize risk obsolescence. Those investing in advanced material science, digitalization, and supply chain fortification are poised to lead the market.

𝗚𝗮𝗶𝗻 𝗩𝗮𝗹𝘂𝗮𝗯𝗹𝗲 𝗜𝗻𝘀𝗶𝗴𝗵𝘁𝘀 𝗳𝗿𝗼𝗺 𝗜𝗻𝗱𝘂𝘀𝘁𝗿𝘆 𝗘𝘅𝗽𝗲𝗿𝘁𝘀 𝘁𝗼 𝗦𝗵𝗮𝗽𝗲 𝗬𝗼𝘂𝗿 𝗚𝗿𝗼𝘄𝘁𝗵 𝗦𝘁𝗿𝗮𝘁𝗲𝗴𝗶𝗲𝘀. 𝗔𝗰𝗰𝗲𝘀𝘀 𝗼𝘂𝗿 𝗦𝗮𝗺𝗽𝗹𝗲 𝗥𝗲𝗽𝗼𝗿𝘁 𝗡𝗼𝘄: https://www.futuremarketinsights.com/reports/sample/rep-gb-17490

𝗥𝗲𝗽𝗼𝗿𝘁 𝗖𝗼𝘃𝗲𝗿𝗮𝗴𝗲 & 𝗗𝗲𝗹𝗶𝘃𝗲𝗿𝗮𝗯𝗹𝗲𝘀:

This comprehensive market report delves into:

- Market sizing (2025–2035) and growth projections

- Hot and Cold Isostatic Pressing technologies

- Application landscape (Aerospace, Medical, Automotive, Energy, etc.)

- Regional and competitive analysis

- Trends in automation, material innovation, and sustainability

- Strategic guidance for stakeholders

𝗞𝗲𝘆 𝗙𝗮𝗰𝘁𝗼𝗿𝘀 𝗦𝗵𝗮𝗽𝗶𝗻𝗴 𝗠𝗮𝗿𝗸𝗲𝘁 𝗗𝘆𝗻𝗮𝗺𝗶𝗰𝘀

The isostatic pressing market is influenced by rapid industrialization, technological convergence, regulatory mandates, and a strong drive toward zero-defect, high-strength components for mission-critical industries.

𝗜𝗻𝘃𝗲𝘀𝘁 𝗶𝗻 𝗛𝗶𝗴𝗵-𝗣𝗲𝗿𝗳𝗼𝗿𝗺𝗮𝗻𝗰𝗲 𝗠𝗮𝘁𝗲𝗿𝗶𝗮𝗹 𝗜𝗻𝗻𝗼𝘃𝗮𝘁𝗶𝗼𝗻

As performance thresholds escalate in aerospace and healthcare, isostatic pressing becomes vital to achieving the highest possible material density and homogeneity. This results in superior fatigue resistance, especially critical for parts exposed to extreme temperatures or pressures.

Manufacturers are heavily investing in new material blends—from titanium alloys for aerospace turbines to bio-compatible metals for implants. These require ultra-precise forming under isostatic pressure, making innovation in material science a competitive necessity.

𝗔𝗹𝗶𝗴𝗻 𝘄𝗶𝘁𝗵 𝗗𝗶𝗴𝗶𝘁𝗮𝗹 𝗮𝗻𝗱 𝗔𝘂𝘁𝗼𝗺𝗮𝘁𝗶𝗼𝗻 𝗧𝗿𝗲𝗻𝗱𝘀

Smart manufacturing is redefining the isostatic pressing process. Integration of AI, IoT, and automation systems in pressing equipment now allows for real-time monitoring, pressure control, and error detection—enhancing reliability while cutting downtime.

Automation also supports regulatory compliance and sustainability, as energy-efficient operations reduce waste and optimize resource use. Companies embracing Industry 4.0 tools are experiencing measurable performance and cost advantages.

𝗦𝘁𝗿𝗲𝗻𝗴𝘁𝗵𝗲𝗻 𝗦𝘂𝗽𝗽𝗹𝘆 𝗖𝗵𝗮𝗶𝗻𝘀 𝗮𝗻𝗱 𝗣𝗮𝗿𝘁𝗻𝗲𝗿𝘀𝗵𝗶𝗽𝘀

To withstand market volatility and ensure faster lead times, key players are establishing regional manufacturing hubs and fostering strategic partnerships. This ensures redundancy, resilience, and a continuous supply of critical parts across geographies.

Collaborations between OEMs, material suppliers, and tech vendors are also helping co-develop next-gen HIP and CIP systems tailored for emerging applications like EV components and space systems.

𝗞𝗲𝘆 𝗧𝗮𝗸𝗲𝗮𝘄𝗮𝘆𝘀

The global isostatic pressing market is undergoing a transformation—one driven by demand for lightweight, defect-free, ultra-durable components. As new applications emerge in aerospace, EVs, and biomedical sectors, the industry is leaning heavily on advanced material processing. The convergence of automation, sustainability, and regulatory precision is separating leaders from laggards. Companies investing in smart, resilient, and energy-efficient technologies are poised for a decade of exponential growth.

𝗕𝗿𝗼𝘄𝘀𝗲 𝗙𝘂𝗹𝗹 𝗥𝗲𝗽𝗼𝗿𝘁 𝗛𝗲𝗿𝗲: https://www.futuremarketinsights.com/reports/isostatic-pressing-market

𝗠𝗮𝘅𝗶𝗺𝗶𝘇𝗶𝗻𝗴 𝗠𝗮𝘁𝗲𝗿𝗶𝗮𝗹 𝗗𝗲𝗻𝘀𝗶𝘁𝘆 𝘄𝗶𝘁𝗵 𝗣𝗿𝗲𝗰𝗶𝘀𝗶𝗼𝗻 𝗜𝘀𝗼𝘀𝘁𝗮𝘁𝗶𝗰 𝗣𝗿𝗲𝘀𝘀𝗶𝗻𝗴 𝗮𝘁 𝗜𝘁𝘀 𝗕𝗲𝘀𝘁

Isostatic pressing delivers near-theoretical material density, making it indispensable in industries where even micro-porosity can mean catastrophic failure. This precision allows engineers to push performance boundaries.

From structural aircraft components to fuel cell parts in hydrogen vehicles, this technology is rewriting the limits of what materials can achieve. Such dense and flawless builds ensure products last longer, perform better, and meet stricter standards.

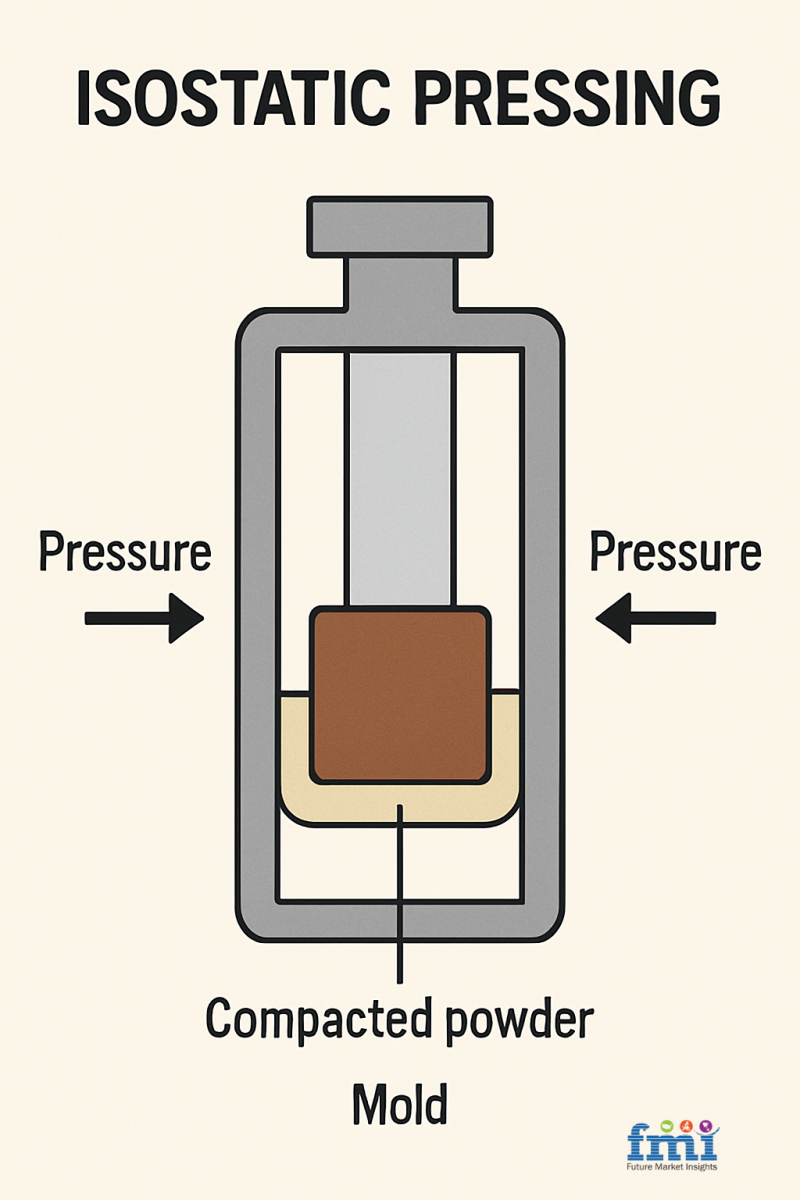

𝗨𝗻𝗶𝗳𝗼𝗿𝗺 𝗣𝗿𝗲𝘀𝘀𝘂𝗿𝗲, 𝗙𝗹𝗮𝘄𝗹𝗲𝘀𝘀 𝗣𝗮𝗿𝘁𝘀 𝗣𝗲𝗿𝗳𝗲𝗰𝘁𝗲𝗱 𝗧𝗵𝗿𝗼𝘂𝗴𝗵 𝗜𝘀𝗼𝘀𝘁𝗮𝘁𝗶𝗰 𝗣𝗿𝗲𝘀𝘀𝗶𝗻𝗴

The uniform application of pressure in all directions ensures consistent quality and eliminates voids or inclusions issues often seen in conventional pressing techniques.

This makes isostatic pressing a gold standard for critical-use components where precision, safety, and structural integrity are non-negotiable. Whether cold or hot, the end result is uncompromising quality.

𝗜𝘀𝗼𝘀𝘁𝗮𝘁𝗶𝗰 𝗣𝗿𝗲𝘀𝘀𝗶𝗻𝗴 𝗠𝗮𝗿𝗸𝗲𝘁 𝗞𝗲𝘆 𝗣𝗹𝗮𝘆𝗲𝗿𝘀:

- Abra Fluid AG – Leading HIP systems manufacturer in Europe with energy-efficient designs.

- American Isostatic Presses (AIP) – U.S.-based innovator in CIP and HIP for defense and aerospace.

- Arconic – Develops high-performance materials processed through HIP for aerospace structures.

- Crystal Technologies – Specializes in HIP for optical and electronic applications.

- Dorst Technologies – Known for automated CIP systems tailored for ceramics and powder metallurgy.

- Engineered Pressure Systems Inc. (EPSI) – Provides both CIP and HIP units with digital integration.

- Fluitron – Focused on high-pressure equipment and compact HIP systems for R&D and pilot production.

𝗔𝗲𝗿𝗼𝘀𝗽𝗮𝗰𝗲-𝗚𝗿𝗮𝗱𝗲 𝗦𝘁𝗿𝗲𝗻𝗴𝘁𝗵 𝗕𝗲𝗴𝗶𝗻𝘀 𝘄𝗶𝘁𝗵 𝗜𝘀𝗼𝘀𝘁𝗮𝘁𝗶𝗰 𝗣𝗿𝗲𝘀𝘀𝗶𝗻𝗴 𝗧𝗲𝗰𝗵𝗻𝗼𝗹𝗼𝗴𝘆

In aerospace, there's no room for defects. Isostatic pressing plays a pivotal role in delivering components with superior fatigue resistance, such as turbine blades, combustor liners, and structural parts.

As new aircraft designs push material science to the limit, HIP ensures near-net shape production and eliminates the micro-cracks or pores that can lead to failure, making it indispensable for flight safety.

𝗥𝗲𝗴𝗶𝗼𝗻𝗮𝗹 𝗔𝗻𝗮𝗹𝘆𝘀𝗶𝘀

- North America: Emphasis on advanced aerospace manufacturing and medical-grade components.

- Latin America: Emerging opportunities in mining and defense applications.

- Western Europe: Focus on regulatory compliance and green energy components.

- Eastern Europe: Gaining traction in automotive and industrial equipment production.

- East Asia: Major growth hub with dominant manufacturing capacity, especially in China and Japan.

- South Asia & Pacific: Rising investments in EVs and additive manufacturing in India and Southeast Asia.

- Middle East & Africa: Growing use in energy and infrastructure projects, particularly in oilfield equipment.

𝗟𝗮𝘁𝗲𝘀𝘁 𝗠𝗮𝗻𝘂𝗳𝗮𝗰𝘁𝘂𝗿𝗶𝗻𝗴 𝗘𝗾𝘂𝗶𝗽𝗺𝗲𝗻𝘁 𝗥𝗲𝗽𝗼𝗿𝘁𝘀: https://www.futuremarketinsights.com/industry-analysis/manufacturing-equipment

𝗧𝗼𝗽 𝗦𝗲𝗴𝗺𝗲𝗻𝘁𝘀 𝗦𝘁𝘂𝗱𝗶𝗲𝗱 𝗶𝗻 𝘁𝗵𝗲 𝗜𝘀𝗼𝘀𝘁𝗮𝘁𝗶𝗰 𝗣𝗿𝗲𝘀𝘀𝗶𝗻𝗴 𝗠𝗮𝗿𝗸𝗲𝘁 𝗥𝗲𝘀𝗲𝗮𝗿𝗰𝗵 𝗥𝗲𝗽𝗼𝗿𝘁

Segmentation by Component:

- Systems

- Services

Segmentation by Type:

- Hot

- Cold

𝗘𝘅𝗽𝗹𝗼𝗿𝗲 𝗙𝗠𝗜’𝘀 𝗘𝘅𝘁𝗲𝗻𝘀𝗶𝘃𝗲 𝗖𝗼𝘃𝗲𝗿𝗮𝗴𝗲 𝗼𝗻 𝗜𝗻𝗱𝘂𝘀𝘁𝗿𝗶𝗮𝗹 𝗔𝘂𝘁𝗼𝗺𝗮𝘁𝗶𝗼𝗻 𝗗𝗼𝗺𝗮𝗶𝗻:

The industrial security system market is expected to grow at a CAGR of 7.5% during the projected period. The market value is expected to increase from USD 55.9 billion in 2024 to USD 115 billion by 2034.

The global Industrial Crystallizer Market is projected to be valued at USD 4.3 billion by 2024 and rise to USD 7.4 billion by 2034. It is expected to grow at a CAGR of 5.6 % from 2024 to 2034.

𝗔𝗯𝗼𝘂𝘁 𝗙𝘂𝘁𝘂𝗿𝗲 𝗠𝗮𝗿𝗸𝗲𝘁 𝗜𝗻𝘀𝗶𝗴𝗵𝘁𝘀 (𝗙𝗠𝗜)

Future Market Insights (FMI) is a leading provider of market intelligence and consulting services, serving clients in over 150 countries. FMI is headquartered in Dubai and has delivery centers in the United Kingdom, the United States, and India. FMI's latest market research reports and industry analysis helps businesses navigate challenges and make critical decisions with confidence and clarity amidst breakneck competition. Our customized and syndicated market research reports deliver actionable insights that drive sustainable growth. A team of expert-led analysts at FMI continuously tracks emerging trends and events in a broad range of industries to ensure that our clients prepare for the evolving needs of their consumers.

Join us as we commemorate 10 years of delivering trusted market insights. Reflecting on a decade of achievements, we continue to lead with integrity, innovation, and expertise.

𝗖𝗼𝗻𝘁𝗮𝗰𝘁 𝗨𝘀:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

Ankush Nikam

Future Market Insights, Inc.

+ +91 90966 84197

email us here

Visit us on social media:

LinkedIn

Facebook

YouTube

X

Other

Distribution channels: Business & Economy

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release