Ready-Mix Concrete Market Value To Hit USD 1,902.2 Bn by 2033, Off-site Production leads with a 73.2% Share

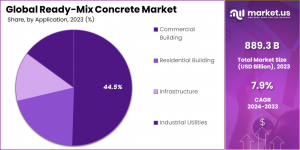

Ready-Mix Concrete Market is expected to be worth around USD 1,902.2 Bn by 2033, up from USD 889.3 Bn in 2023, and grow at a CAGR of 7.9% from 2024 to 2033.

NEW YORK, NY, UNITED STATES, January 27, 2025 /EINPresswire.com/ -- The Global Ready-Mix Concrete Market has experienced significant growth over the past decade, driven by an upsurge in construction activities across various sectors, including residential, commercial, and infrastructure. Ready-mix concrete (RMC) is a tailor-made concrete that is manufactured in a factory or within a batching plant based on the standard required specifications. The premixed solution is then delivered to the construction site in transit mixers and can be used straight away without further treatment.

This market's growth is predominantly fueled by the rapid urbanization and industrialization in emerging economies. The push towards infrastructural development in countries like China, India, and Brazil has resulted in an increased demand for buildings, highways, and bridges, all of which require large amounts of concrete. Furthermore, the growing preference for sustainable building materials has also spurred the use of ready-mix concrete, which, due to its precise mixture and reduced waste, is considered more environmentally friendly compared to traditional concrete mixing methods.

Major companies have been actively expanding their geographical presence and production capacities through acquisitions and opening new plants. The competitive landscape is also marked by a strong focus on research and development activities aimed at enhancing the quality and sustainability of the product. Innovations such as the introduction of green concrete and self-compacting concretes are examples of industry efforts to align with global sustainability trends and stricter regulations regarding construction materials.

Driving factors for the market include the superior durability and ability to customize ready-mix concrete, making it a preferable choice for complex construction projects. The reliability of delivery and the efficiency of using ready-mix concrete reduce overall building times and construction costs, making it a strategic choice for contractors and developers. Moreover, governmental regulations promoting safer construction practices have led to increased compliance by using standardized and quality-assured products like RMC.

The future growth opportunities for the ready-mix concrete market appear promising. With the increasing focus on infrastructure and residential construction in developing nations, along with the rising adoption of new technologies in the construction process, the demand for ready-mix concrete is anticipated to rise. Additionally, the shift towards eco-friendly and sustainable construction practices globally will push the development of innovative, environmentally sustainable ready-mix products. This includes the utilization of recycled materials and the development of new mixtures that minimize environmental impact without compromising quality.

The global ready-mix concrete market is set to expand further as it continues to play a crucial role in meeting the construction needs of a rapidly urbanizing world. The industry's ability to innovate and adapt to both technological advancements and stringent environmental regulations will likely dictate the pace and direction of its growth in the coming years. As infrastructure needs grow and environmental considerations become even more pressing, ready-mix concrete will remain a vital component of the global construction industry.

👉 𝐌𝐚𝐤𝐞 𝐜𝐨𝐧𝐟𝐢𝐝𝐞𝐧𝐭 𝐝𝐞𝐜𝐢𝐬𝐢𝐨𝐧𝐬 𝐮𝐬𝐢𝐧𝐠 𝐨𝐮𝐫 𝐢𝐧𝐬𝐢𝐠𝐡𝐭𝐬 𝐚𝐧𝐝 𝐚𝐧𝐚𝐥𝐲𝐬𝐢𝐬. 𝐑𝐞𝐪𝐮𝐞𝐬𝐭 𝐚 𝐏𝐃𝐅 𝐒𝐚𝐦𝐩𝐥𝐞 𝐑𝐞𝐩𝐨𝐫𝐭@ https://market.us/report/ready-mix-concrete-market/free-sample/

Key Takeaways

• The Global Ready-Mix Concrete Market is expected to be worth around USD 1,902.2 Billion by 2033, up from USD 889.3 Billion in 2023, and grow at a CAGR of 7.9% from 2024 to 2033.

• The Ready-Mix Concrete Market is dominated by Transit Mixed Concrete with a 65.4% share.

• Off-site production leads in the Ready-Mix Concrete Market, capturing a significant 73.2% market portion.

• Barrel trucks or in-transit mixers are the preferred equipment, holding a 77.2% stake in the market.

• Commercial buildings are a major application in the Ready-Mix Concrete Market, accounting for 44.5%.

• The Asia-Pacific Ready-Mix Concrete Market dominates with 57%, valued at USD 510.4 billion.

Ready-Mix Concrete Top Trends

1. Sustainability Practices: Companies are increasingly incorporating green practices into their operations, such as using recycled materials and reducing carbon emissions. This shift is in response to growing environmental concerns and regulatory pressures.

2. Technological Integration: Advanced technologies like BIM (Building Information Modeling) and IoT (Internet of Things) are becoming integral in optimizing production and delivery processes. These technologies help in tracking, managing, and improving efficiency.

3. Custom Mixes and High-Performance Concrete: There is a rising demand for specialized concrete mixes that offer enhanced performance characteristics such as increased strength, durability, and resistance to environmental conditions.

4. Regulatory Compliance: Firms are focusing more on complying with stringent environmental and safety regulations to avoid penalties and enhance market reputation. This includes adhering to updated standards and employing safer, more sustainable practices.

5. Automation and Robotics: Automation in production processes and the use of robotics in concrete delivery and placement are growing trends. These advancements help in maintaining quality, reducing labor costs, and improving safety on construction sites.

Key Market Segments

By Type Analysis

Transit Mixed Concrete dominates the market with a 65.4% share, valued for its efficiency and reliability. This method mixes concrete en route to construction sites, ensuring optimal freshness and workability. It is preferred for its speed and ability to meet modern construction standards. Shrink Mixed Concrete holds a significant portion, though less than Transit Mixed, offering advantages like improved workability and lower water content, making it suitable for precision-demanding applications. Central Mixed Concrete, though less common, plays a crucial role in high-volume projects where consistent quality is essential. It's preferred for its ability to provide customized mixes under controlled conditions.

By Production Analysis

Off-site Production leads with a 73.2% market share, favored for its ability to produce consistent quality and reduce material waste through controlled mixing environments. It benefits from economies of scale, which lower costs and minimize environmental impact. On-site Production remains vital for projects needing immediate mixing or where logistical challenges prevent off-site preparation. This method offers flexibility to adjust mix properties on the spot.

By Mixer Type Analysis

Barrel Trucks/In-transit Mixers are the primary equipment used, accounting for 77.2% of operations. These mixers are essential for large-scale projects requiring timely and consistent concrete delivery. Volumetric Mixers, though less prevalent, provide unique benefits by allowing on-site mixing, offering flexibility and control over the concrete composition, crucial for projects with variable demands.

By Application Analysis

Commercial Building uses account for 44.5% of the market, driven by global economic growth and urbanization, which fuel the expansion of commercial spaces requiring durable and aesthetically pleasing concrete. Residential Buildings, Infrastructure, and Industrial Utilities also contribute significantly, each serving specific needs ranging from residential structures to public utilities and heavy-duty industrial applications.

Key Market Segments List

By Type

• Transit Mixed Concrete

• Shrink Mixed Concrete

• Central Mixed Concrete

By Production

• On-site

• Off-site

By Mixer Type

• Volumetric

• Barrel Truck/In-transit mixer

By Application

• Commercial Building

• Residential Building

• Infrastructure

• Industrial Utilities

Regional Analysis

Asia-Pacific is the leading region with a 57% market share, primarily driven by dynamic growth in China and India. The region's market value is propelled by extensive urbanization and infrastructural developments. North America and Europe display mature market characteristics with a focus on renovating infrastructure and adopting sustainable practices. Middle East & Africa and Latin America show varied growth influenced by regional economic strategies and urban development projects, with the Middle East & Africa experiencing growth from infrastructure investments in the GCC countries.

Regulations On the Ready-Mix Concrete Market

1. Environmental and Safety Regulations: The industry faces stringent environmental regulations, especially concerning air quality and water usage. Companies must comply with these to avoid hefty fines and operational disruptions. Safety regulations are also crucial, ensuring worker protection during concrete mixing and handling processes.

2. ASTM and ACI Standards: ASTM C94 provides specifications for ready-mixed concrete, including setting time limits now customizable based on client or producer needs, which helps in adapting to various project demands. ACI offers guidelines ensuring concrete structural integrity and safety in various construction environments.

3. OSHA Compliance: Adhering to Occupational Safety and Health Administration (OSHA) standards is essential, especially in terms of confined spaces, exposure to harmful substances, and the use of protective equipment. State plans may have more stringent or additional requirements compared to federal standards.

4. Local and State Building Codes: Building codes at local and state levels often incorporate international standards that dictate specific requirements for concrete construction to ensure safety, sustainability, and proper construction practices.

👉 𝐓𝐨 𝐆𝐞𝐭 𝐌𝐨𝐦𝐞𝐧𝐭 𝐀𝐜𝐜𝐞𝐬𝐬, 𝐁𝐮𝐲 𝐑𝐞𝐩𝐨𝐫𝐭 𝐇𝐞𝐫𝐞: 𝐒𝐜𝐨𝐫𝐞 𝐔𝐩 𝐭𝐨 𝟑𝟎% 𝐎𝐟𝐟! https://market.us/purchase-report/?report_id=135341

Key Players

• ACC Limited

• Barney & Dickenson, Inc.

• Buzzi Unicem SpA

• CEMEX, S.A.B. de C.V.

• China National Building Material Group Corporation

• Dillon Bros Ready Mix Concrete

• Hanson Cement Ltd.

• Heidelberg Materials AG

• HEIDELBERGCEMENT AG

• HOLCIM

• Italcementi Group

• LafargeHolcim

• Livingston’s Concrete Service, Inc.

• M. I. Cement Factory Limited.

• R. W. Sidley, Inc.

• U.S. Concrete, Inc.

• UltraTech Cement Ltd.

• Vicat S.A.

Conclusion

The Ready-Mix Concrete industry is poised for substantial growth and transformation, driven by advancements in technology, sustainability efforts, and regulatory compliance. As companies continue to integrate digital tools like IoT and BIM, they enhance operational efficiencies and project management capabilities. Furthermore, the push towards environmentally sustainable practices, including the use of recycled materials and low-carbon technologies, reflects the industry's response to global environmental concerns. With ongoing innovations in concrete mixes and delivery methods, the sector is well-equipped to meet the evolving demands of construction projects worldwide. Thus, stakeholders in the Ready-Mix Concrete market must stay agile and forward-thinking to leverage these trends for competitive advantage and sustainable growth.

Lawrence John

Prudour

+91 91308 55334

Lawrence@prudour.com

Distribution channels: Building & Construction Industry

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release